The Most Common Flooring Showroom Augusta Flooring Pros Debate Isn't As Black And White As You Might Think

If you want your custodian, to invest thousands of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty calendar year old Terrazzo, or Marble flooring, by all means, GO FOR IT.

THEN WHO MUST I TALK TO?

You can hire an extremely reputable Concrete Grinding and Polishing professional, who only does floors, for a lot less money than you would expect. They can grind, polish, seal, dye, or apply one of hundreds of items to your ground for the same or less overall than re-applying tile which does not have the same resiliency, and longevity as the previous asbestos tile products.

You can install carpet which typically has no a lot more than 5-7 year life span. Or you can go with a dyed flooring that will outlast all of us. Your options are endless, but you need to find a contractor that you could trust, and execute a little homework prior to making your decision. Some may recommend products that you'll call floor color or epoxy. What are the advantages or disadvantages of that type of product? There's probably nothing wrong with that, nevertheless, you need a few facts before making https://en.search.wordpress.com/?src=organic&q=flooring store your decision.

Floor paint that you'll typically buy in a home improvement or hardware shop is fairly easy to use, but generally will not endure to much traffic, either tires or foot traffic. And to be able to obtain the best results you nevertheless still need to perform the majority of the prep that would be necessary for the other items. Epoxy is more durable once it is cured, but can be damaged if exposed to some abuse before it is totally cured. (Two times for foot visitors) and (Up to thirty days for wheel visitors). If you cannot live with that, then you have to consider other options.

WARNING!

Epoxy is not easily repairable, and bears "NO " warranty, if strict recommendation for it's care aren't observed. Don't expect the contractor another a week after your beautiful ground was redone to fix tire marks in your shop. It's not possible! If you want a floor that's less sensitive, you then should probably consider program of a penetrating dye, followed by sealer to give you an attractive floor surface finish which will be less susceptible to marring and scratching.

Okay, so today the questions. Are these kinds of floor finishes slippery? The easiest method to explain that is to describe the grinding and polishing procedure.

When cement is poured you are bound to have some inconsistencies. Why? Perhaps you have ever poured concrete, or watched it being poured? Regardless of how great you are, or how good your tools is, getting a large slab of concrete totally level, is hard. The loads of concrete from the prepared mix company can be inconsistent from one load to the next. Most concrete is normally poured in http://query.nytimes.com/search/sitesearch/?action=click&contentCollection®ion=TopBar&WT.nav=searchWidget&module=SearchSubmit&pgtype=Homepage#/flooring store the summer when temperature and wind make a difference the rate of period for the concrete to dry. Whether it's poured in the fall or wintertime drying and curing agents are put into the mix which can also result in problems later on. Important thing is, the finished floor can have lots of imperfections flooring stores near me in it that you can deal with.

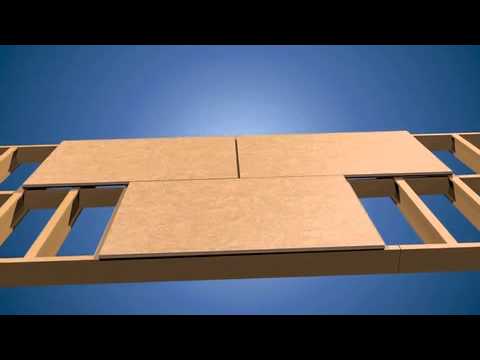

The newest equipment which is normally used by a concrete restoration company is meant to apply more than enough pressure to the diamond cups or "stones" under the machine that given enough time, will do an excellent job, of leveling your floor. The grinding tools generally weighs between 1,200 and 2,500 pounds which is a whole lot more head pressure than your swing buffer. A typical grinding machine will probably have no less than a dozen stone which submit a synchronized movement to pulverize the top 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Why is it softer? Because mainly because you will recall, I discussed the curing brokers which is used at the time the concrete was poured. That product is intended to harden the very best surface, and needs to be taken off before you can really enter "Mechanically Changing" the floor. So you've got your skin from the floor. What's next?

Next, you go to a little finer group of grinding stone to keep the grinding/leveling procedure. You go in right lines in a precise area to ensure each portion of floor is ground evenly. All floors will require overlapping with the machine. Some will require changing path with the machine to level the floor properly. All floors will require edging against wall space and in doorways to grind and level the floor adequately. All this requires floor technicians with a fairly significant amount of knowledge and training to accomplish the job the right way.

Doesn't this create a lot of dust? Good question. Yes it can, but depending on the quality of the grinding devices which include some pretty high effectiveness and costly vacuums with dual "Hepa" filter systems, that are attached to the grinder, 90-95% of the dirt is sucked directly into the vacuum to become removed. What else?

7 Horrible Mistakes You're Making With Top Rated Flooring Companies

If you want your custodian, to invest thousands of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty year old Terrazzo, or Marble ground, you should, GO FOR IT.

THEN WHO SHOULD I TALK TO?

You can hire a very reputable Concrete Grinding and Polishing professional, who only does floors, for a lot less money than you'll expect. They are able to grind, polish, seal, dye, or apply among hundreds of products to your ground for the same or less money than re-applying tile which https://www.washingtonpost.com/newssearch/?query=flooring store doesn't have the same resiliency, and longevity as the previous asbestos tile products.

You can install carpet which typically does not have any more than 5-7 year life expectancy. Or you can proceed with a dyed floor that will outlast all of us. Your options are endless, but you need to find a contractor that you could trust, and do a little homework before making your decision. Some may suggest products that you'll call floor paint or epoxy. What are advantages or disadvantages of that type of product? There's most likely nothing incorrect with that, nevertheless, you want a few facts before making your decision.

Floor paint that you'll typically buy in a home improvement or hardware shop is fairly simple to use, but generally will not endure to much traffic, either tires or feet traffic. And to be able to obtain the best results you nevertheless still need to perform the majority of the prep that might be necessary for the other items. Epoxy is more durable once it really is cured, but could be damaged if exposed to some abuse before it is totally cured. (Two days for foot traffic) and (Up to four weeks for wheel traffic). If you can't live with that, you then have to consider other options.

WARNING!

Epoxy isn't easily repairable, and carries "NO " guarantee, if strict recommendation for it's care aren't observed. Don't expect the contractor another weekly after your beautiful floor was redone to fix tire marks in your shop. It's not possible! If you want a floor that is less sensitive, then you should probably consider software of a penetrating dye, accompanied by sealer to provide you with http://edition.cnn.com/search/?text=flooring store an attractive floor end which will likely be less vunerable to marring and scratching.

Okay, so now the queries. Are these types of flooring finishes slippery? The best way to explain that is to explain the grinding and polishing procedure.

When concrete is poured you are bound to involve some inconsistencies. Why? Perhaps you have ever poured cement, or watched it being poured? No matter how great you are, or how great your equipment is, getting a large slab of concrete completely level, is next to impossible. The loads of concrete from the prepared mix company can be inconsistent from one load to another. Most concrete is definitely poured in the summertime when high temperature and wind make a difference the rate of time for the concrete to dried out. If it's poured in the fall or wintertime drying and curing agents are put into the mix which can also result in problems later on. Important thing is, the finished ground can have plenty of imperfections in it so that you can deal with.

The most recent equipment which is generally utilized by a concrete restoration company is meant to apply more than enough pressure to the diamond cups or "stones" under the machine that given enough time, will do an excellent job, of leveling your floor. The grinding apparatus generally flooring stores near me weighs between 1,200 and 2,500 pounds which is a whole lot more head pressure than your swing buffer. A typical grinding machine will probably have no significantly less than twelve stone which turn in a synchronized motion to pulverize the very best 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Why is it softer? Because mainly because you will recall, I talked about the curing agents which is applied at that time the concrete was poured. That product is intended to harden the very best surface, and must be used off before you can really enter "Mechanically Changing" the ground. So you've got the skin off of the floor. What's next?

Next, you go to a little finer set of grinding stone to keep the grinding/leveling procedure. You go in direct lines in a defined area to ensure each section of floor is surface evenly. All floors will require overlapping with the device. Some will demand changing path with the machine to level the ground properly. All floors will require edging up against wall space and in doorways to grind and level the ground adequately. All of this requires floor professionals with a pretty significant amount of experience and training to accomplish the job the proper way.

Doesn't this create a lot of dust? Good query. Yes it does, but depending on the quality of the grinding gear which include some pretty high efficiency and expensive vacuums with dual "Hepa" filters, that are mounted on the grinder, 90-95% of the dust is sucked directly into the vacuum to become removed. What else?

15 Hilarious Videos About Flooring Showroom Augusta Flooring Pros

If you want your custodian, to invest thousands of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty yr old Terrazzo, or Marble floor, you should, GO FOR IT.

THEN WHO SHOULD I TALK TO?

You can hire a very reputable Concrete Grinding and Polishing professional, who just does floors, for much less money than you'll expect. They are able to grind, polish, seal, dye, or apply one of hundreds of items to your floor for the same or less money than re-applying tile which doesn't have the same resiliency, and longevity as the previous asbestos tile products.

You can install carpet which typically does not have any a lot more than 5-7 year life expectancy. Or you can move with a dyed floor that will outlast all of us. Your options are endless, but you need to look for a contractor that you can trust, and do a little homework before making your decision. Some may recommend products that you would call floor color or epoxy. What are advantages or disadvantages of this type of product? There's most likely nothing wrong with that, but you want a few facts prior to making your decision.

Floor paint that you would typically buy in a home improvement or hardware shop is fairly easy to use, but generally won't endure to much visitors, either tires or feet traffic. And to be able to have the best results you nevertheless still http://www.thefreedictionary.com/flooring store need to do the majority of the prep that might be essential for the other products. Epoxy is stronger once it really is cured, but could be damaged if subjected to some abuse before it is completely cured. (Two times for foot visitors) and (Up to thirty days for wheel traffic). If you cannot live with that, then you have to consider other options.

WARNING!

Epoxy isn't easily repairable, and bears "NO " guarantee, if strict recommendation for it's care aren't observed. Don't expect the contractor another weekly after your beautiful flooring was redone to repair tire marks in your store. It's not possible! If you want a floor that is less sensitive, then you should probably consider software of a penetrating dye, accompanied by sealer to give you an attractive floor finish which will probably be less susceptible to marring and scratching.

Okay, so now the questions. Are these types of flooring finishes slippery? The easiest method to explain that's to describe the grinding and polishing procedure.

When cement is poured you are bound to involve some inconsistencies. Why? Perhaps you have ever poured cement, or watched it getting poured? Regardless of how good you are, or how great your equipment is, getting a large slab of concrete completely level, is next to impossible. The plenty of concrete from the ready mix company can be inconsistent in one load to another. Most concrete is normally poured in the summertime when high temperature and wind make a difference the rate of period for the concrete to dried out. Whether it's poured in the fall or winter season drying and curing brokers are added to the mix that may also result in problems later on. Bottom line is, the finished ground can have plenty of imperfections in it that you can deal with.

The most recent equipment which is normally used by a concrete restoration company is intended to flooring stores near me apply more than enough pressure to the diamond cups or "stones" beneath the machine that given enough time, will do an excellent job, of leveling your floor. The grinding devices generally weighs between 1,200 and 2,500 pounds which is a whole lot more mind pressure than your swing buffer. A typical grinding machine is going to have no less than twelve stone which turn in a synchronized movement to pulverize the top 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Why is it softer? Because simply because you will recall, I discussed the curing brokers which is applied at that time the concrete was poured. That product is meant to harden the top surface, and needs to be used off before you really enter "Mechanically Changing" the ground. So you've got the skin off of the floor. What's next?

Next, you go to a little finer set of grinding stone to continue the grinding/leveling procedure. You go in straight lines in a precise area to make sure each portion of floor is surface evenly. All floors will demand overlapping with the machine. Some will require changing direction with the device to level the floor properly. All flooring will require edging against walls and in doorways to grind and level the floor adequately. All this requires floor specialists with a pretty significant amount of knowledge and training to do the job the right way.

Doesn't this create a lot of dust? Good question. Yes it can, but depending on the http://www.bbc.co.uk/search?q=flooring store quality of the grinding equipment which includes some pretty high performance and costly vacuums with double "Hepa" filters, that are attached to the grinder, 90-95% of the dust is sucked right into the vacuum to end up being disposed of. What else?

15 Terms Everyone In The Flooring Stores Near Me Industry Should Know

If you would like your custodian, to spend hundreds of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty season old Terrazzo, or Marble ground, by all means, GO FOR IT.

THEN WHO SHOULD I TALK TO?

You can hire a very reputable Concrete Grinding and Polishing professional, who just does floors, for a lot less money than you'll expect. They can grind, polish, seal, dye, or apply among hundreds of items to your ground for the same or less money than re-applying tile which does not have the same resiliency, and longevity as the prior asbestos tile products.

You can install carpet which typically has no a lot http://www.thefreedictionary.com/flooring store more than 5-7 year life span. Or you can go with a dyed ground that will outlast all of us. Your options are endless, but you need to find a contractor that you could trust, and execute a little homework prior to making your decision. Some may suggest products that you'll call floor paint or epoxy. What exactly are advantages or disadvantages of this kind of product? There's most likely nothing wrong with that, but you need a few facts before making your decision.

Floor paint that you'll typically buy in a home improvement or hardware store is fairly simple to use, but generally won't hold up to much visitors, either tires or foot traffic. And in order to find the best results you nevertheless still https://en.search.wordpress.com/?src=organic&q=flooring store need to flooring stores near me perform most of the prep that might be essential for the other products. Epoxy is stronger once it is cured, but could be damaged if exposed to some abuse before it is totally cured. (Two days for foot traffic) and (Up to thirty days for wheel traffic). If you can't live with that, you then need to consider other options.

WARNING!

Epoxy is not easily repairable, and bears "NO " warranty, if strict recommendation for it's care aren't observed. Don't expect the contractor to come back a week after your beautiful flooring was redone to repair tire marks in your shop. It's not possible! If you want a floor that is less sensitive, then you should probably consider software of a penetrating dye, accompanied by sealer to give you an attractive floor end which will likely be less susceptible to marring and scratching.

Okay, so today the queries. Are these kinds of ground finishes slippery? The best way to explain that is to describe the grinding and polishing process.

When cement is poured you are bound to have some inconsistencies. Why? Perhaps you have ever poured cement, or watched it being poured? No matter how great you are, or how great your apparatus is, getting a big slab of concrete completely level, is next to impossible. The loads of concrete from the prepared mix company can be inconsistent in one load to the next. Most concrete is normally poured in the summer when high temperature and wind can affect the rate of period for the concrete to dried out. Whether it's poured in the fall or winter season drying and curing brokers are put into the mix that may also lead to problems later on. Important thing is, the finished floor can have plenty of imperfections in it so that you can deal with.

The most recent equipment which is normally utilized by a concrete restoration company is meant to apply enough pressure to the diamond cups or "stones" under the machine that given enough time, will do an excellent job, of leveling your floor. The grinding tools generally weighs between 1,200 and 2,500 pounds which really is a whole lot more head pressure than your swing buffer. A typical grinding machine will probably have no less than twelve stone which submit a synchronized motion to pulverize the top 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Exactly why is it softer? Because as you will recall, I discussed the curing agents which is applied at the time the concrete was poured. That product is meant to harden the top surface, and needs to be taken off before you can really get into "Mechanically Changing" the floor. So you've got your skin from the floor. What's next?

Next, you visit a little finer group of grinding stone to continue the grinding/leveling procedure. You go in straight lines in a precise area to ensure each section of floor is floor evenly. All flooring will demand overlapping with the device. Some will require changing direction with the machine to level the floor properly. All flooring will require edging against wall space and in doorways to grind and level the floor adequately. All this requires floor technicians with a pretty significant amount of encounter and training to accomplish the job the proper way.

Doesn't this create a whole lot of dust? Good query. Yes it does, but depending on the quality of the grinding tools which includes some pretty high efficiency and expensive vacuums with double "Hepa" filters, that are attached to the grinder, 90-95% of the dust is sucked right into the vacuum to become disposed of. What else?

14 Cartoons About Augusta Flooring Company Flooring Pros That'll Brighten Your Day

If you want your custodian, to invest thousands of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty calendar year old Terrazzo, or Marble floor, by all means, GO FOR IT.

THEN WHO MUST I TALK TO?

You can hire a very reputable Concrete Grinding and Polishing professional, who only does floors, for a lot less money than you'll expect. They can grind, polish, seal, dye, or apply among hundreds of products to your floor for the same or less overall than re-applying tile which does not have the same resiliency, and longevity as the previous asbestos tile products.

You can install carpet which typically does not have any more than 5-7 year life span. Or you can go with a dyed ground that will outlast most of us. The options are endless, nevertheless, you need to find a contractor flooring stores near me that you could trust, and do a little homework before making your decision. Some may recommend products that you'll call floor paint or epoxy. What exactly are https://www.washingtonpost.com/newssearch/?query=flooring store advantages or disadvantages of that kind of product? There's probably nothing incorrect with that, but you need a few facts prior to making your decision.

Floor paint that you'll typically buy in a home improvement or hardware store is fairly easy to use, but generally won't endure to much visitors, either tires or feet traffic. And in order to get the best results you nevertheless still need to perform the majority of the prep that might be necessary for the other products. Epoxy is stronger once it really is cured, but could be damaged if subjected to some abuse before it is totally cured. (Two times for foot visitors) and (Up to four weeks for wheel visitors). If you cannot live with that, you then need to consider other options.

WARNING!

Epoxy isn't easily repairable, and carries "NO " guarantee, if strict recommendation for it's care aren't observed. Don't expect the contractor to come back weekly after your beautiful ground was redone to repair tire marks in your store. It's not possible! If you prefer a floor that is less sensitive, then you should probably consider application of a penetrating dye, accompanied by sealer to give you an attractive floor surface finish which will probably be less vunerable to marring and scratching.

Okay, so now the questions. Are these types of floor finishes slippery? The easiest method to explain that's to describe the grinding and polishing procedure.

When concrete is poured you are bound to have some inconsistencies. Why? Have you ever poured cement, or watched it being poured? No matter how great you are, or how good your devices is, getting a sizable slab of concrete totally level, is next to impossible. The loads of concrete from the prepared mix company could be inconsistent in one load to another. Most concrete is certainly poured in the summer when heat and wind make a difference the rate of period for the concrete to dry. If it's poured in the fall or winter drying and curing brokers are added to the mix that may also lead to problems later on. Important thing is, the finished ground can have plenty of imperfections in it for you to deal with.

The latest equipment which is generally utilized by a concrete restoration company is intended to apply enough pressure to the gemstone cups or "stones" under https://en.wikipedia.org/wiki/?search=flooring store the machine that given enough time, will do an excellent job, of leveling your floor. The grinding apparatus generally weighs between 1,200 and 2,500 pounds which really is a whole lot more head pressure than your swing buffer. An average grinding machine will have no less than twelve stone which submit a synchronized movement to pulverize the very best 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Why is it softer? Because simply because you will recall, I talked about the curing agents which is used at the time the concrete was poured. That product is intended to harden the top surface, and must be taken off before you can really enter "Mechanically Changing" the floor. So you've got the skin from the floor. What's next?

Next, you visit a little finer group of grinding stone to keep the grinding/leveling process. You go in right lines in a precise area to make sure each portion of floor is ground evenly. All floors will demand overlapping with the device. Some will require changing direction with the machine to level the floor properly. All flooring will require edging up against wall space and in doorways to grind and level the floor adequately. All of this requires floor professionals with a fairly significant amount of knowledge and training to do the job the proper way.

Doesn't this create a whole lot of dust? Good issue. Yes it does, but depending on the standard of the grinding equipment which includes some pretty high efficiency and costly vacuums with dual "Hepa" filter systems, that are mounted on the grinder, 90-95% of the dirt is sucked right into the vacuum to end up being disposed of. What else?

Addicted To Flooring Company Near Me? Us Too. 6 Reasons We Just Can't Stop

What is all of the discuss "Polished Concrete Floors?" Polishing and grinding concrete flooring is a topic of discussion over the past few years, and I've been asked so often what it's about, that I made a decision to write this article. Hard surface flooring have been around since the period of the Roman Empire. It took a massive quantity of labor, and lots of ingenuity to split huge stones, and hone them down to make slabs ideal for flooring in buildings. To get more specific than that is mind boggling, kind of like, "How did they build the Pyramids in Egypt? " My answer is, "I sort of know how they did it, but I'm glad I didn't have to do the work".

Fast forward a little, and we come to newer times when people found out that you could combine Portland (a clay compound) with sand, rock and water, to make the first concrete. The mixtures have been tweaked through the years, however the process has virtually remained the same. Contractors possess used different curing brokers, have implemented the use of steel bar to hopefully prevent concrete from cracking, and have implemented various kinds of moisture barriers to boost on the finished product.

Building owners have needed different types of flooring more than the concrete to provide a building a warmer, and cleaner feel. In industrial facilities they have used tile, rolled linoleum, floor color, or epoxy to give a creating a more appealing appearance, and make it easier to clean than bare concrete. That works for some time, but everyone of these products ultimately wears out and needs alternative. That brings us up for this time.

Since early in the twentieth century, scientist experimented with different compositions to create a flooring items that would last for a long period of period. Some tile items were made up of an asphalt foundation. Some were made stronger by adding asbestos to the blend. Don't get me wrong, it was a good product, and after 40 years in the business, I've seen some asbestos tile that dates back at least 60 years, and is still in great condition. The issue is that asbestos is certainly a Carcinogen, and once the tile is broken, or disturbed, you can very easily https://www.washingtonpost.com/newssearch/?query=flooring be exposing you to ultimately cancer leading to agents, in the air flow. Guess who arrives on the noticed when something similar to that can be reported? You got it! The Guys with Light Hats Riding on White Horses. Now you have for the asbestos abatement crews. Can you say, BIG BUCKS?

Abatement is a tedious, and frustrating process, but it has to be done, before you begin the process of restoring the cement flooring underneath. You cannot do it yourself! Asbestos Abatement requires a lot of time of training, qualification, annual re-certification, special tools, and people who are crazy more than enough to wish to accomplish it. Just kidding! Luckily, there are individuals who enjoy that kind of function, and take pride in providing a great finished product.

I, much prefer coming in after the cleanup has been completed. Concrete grinding products has been around the advancement stage for over 70 years. Changes with some companies specifically during the last 5-10 years have been dramatic. Why? Because, the federal government has determined there are enough floors out there, that are wearing out or broken, that they need to part of with some requirements for removal, because so many of these floors are in public buildings. So what are my choices as a services or building manager? Initial, you should go on-line, and look for a very trustworthy asbestos abatement firm, and get an estimate. Second, you should find reputable Concrete Restoration firm to give you your options at their disposal. Next, you are likely to have to put together a cover the completion of the work, so that you, your plank of directors, or your college board is not shocked by the cost of the completed project. And lastly, you will definitely have to routine the work.

Due to the price of the abatement, and the fact that they will have to tent off areas as the abatement is going on, you will have some dependence on some logistical planning. Everything you don't wish to accomplish is put it off, hoping the issue will treatment itself, or go away. That's not going to happen. It doesn't happen that often, but I have seen instances where in fact the inspectors come in and demand that the problem is corrected prior to the building can be used again. That's ugly!

Do you know the definition of the term, "Problem"? It 's a situation that you don't cope with. There are currently thousands of floors in public and private schools, colleges, universities, court homes, and other public buildings who've been fore warned that they have to eliminate asbestos floors.

In the last five to ten years, they have continually been given an extension, or given a "pass", because of the fact that "They don't really have money in their BUDGET". In fact, the 1st time I noticed that was 1981, and the spending budget offers gotten tighter every year. This has result in the advent of tools and grinding pads for "The DO-IT-YOURSELF", types. Do you know what? They don't work.

If you would like your custodian, to invest hundreds of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty yr old Terrazzo, or Marble flooring, by all means, GO FOR IT.

THEN WHO SHOULD I TALK TO?

You can hire an extremely reputable Concrete Grinding and Polishing professional, who just does floors, for much less money than you'll expect. They can grind, polish, seal, dye, or apply among hundreds of products to your floor for the same or less money than re-applying tile which does not have the same resiliency, and longevity as the previous asbestos tile https://www.evernote.com products.

You can install carpet which typically does not have any more than 5-7 year life expectancy. Or you can proceed with a dyed flooring that will outlast most of us. Your options are endless, nevertheless, you need to look for a contractor that you could trust, and execute a little homework before making your decision. Some may recommend products that you'll call floor paint or epoxy. What are advantages or disadvantages of that kind of product? There's probably nothing wrong with that, but you want a few facts before making your decision.

Floor paint that you would typically buy in a home improvement or hardware store is fairly easy to use, but generally won't hold up to much visitors, either tires or foot traffic. And to be able to obtain the best results you nevertheless still need to perform the majority of the prep that might be essential for the other items. Epoxy is stronger once it is cured, but could be damaged if subjected to some abuse before it is completely cured. (Two times for foot visitors) and (Up to thirty days for wheel visitors). If you cannot live with that, then you need to consider other options.

WARNING!

Epoxy is not easily repairable, and carries "NO " warranty, if strict recommendation for it's care are not observed. Don't expect the contractor to come back weekly after your beautiful ground was redone to repair tire marks in your store. It's not possible! If you want a floor that is less sensitive, you then should probably consider software of a penetrating dye, followed by sealer to give you an attractive floor end which will probably be less susceptible to marring and scratching.

Okay, so now the questions. Are these kinds of floor finishes slippery? The easiest method to explain that is to explain the grinding and polishing procedure.

When concrete is poured you are bound to have some inconsistencies. Why? Perhaps you have ever poured concrete, or watched it getting poured? Regardless of how great you are, or how great your equipment is, getting a big slab of concrete completely level, is next to impossible. The loads of concrete from the ready mix company can be inconsistent in one load to the next. Most concrete can be poured in the summer when temperature and wind can affect the rate of period for the concrete to dried out. If it's poured in the fall or winter drying and curing brokers are put into the mix which can also lead to problems later on. Bottom line is, the finished floor can have plenty of imperfections in it for you to deal with.

The most recent equipment which is generally used by a concrete restoration company is intended to apply plenty of pressure to the gemstone cups or "stones" under the machine that given plenty of time, will do an excellent job, of leveling your floor. The grinding equipment generally weighs between 1,200 and 2,500 pounds which really is a whole lot more head pressure than your swing buffer. A typical grinding machine will probably have no significantly less than a dozen stone which submit a synchronized movement to pulverize the very best 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Exactly why is it softer? Because mainly because you will recall, I discussed the curing brokers which is applied at that time the concrete was poured. That product is meant to harden the very best surface, and must be used off before you can really enter "Mechanically Changing" the floor. So you've got the skin off of the floor. What's next?

Next, you go to a little finer set of grinding stone to keep the grinding/leveling procedure. You go in direct lines in a precise area to make sure each portion of floor is ground evenly. All flooring will require overlapping with the machine. Some will demand changing path with the machine to level the ground properly. All flooring will require edging against walls and in doorways to grind and level the floor adequately. All this requires floor technicians with a fairly significant amount of experience and training to do the job the right way.

Doesn't this create a whole lot of dust? Good issue. Yes it can, but depending on the standard of the grinding equipment which includes some pretty high performance and costly vacuums with double "Hepa" filter systems, that are attached to the grinder, 90-95% of the dirt is sucked directly into the vacuum to end up being removed. What else?

How about noise? The grinders are generally not that noisy. The vacuums are, but can generally end up being operated so that they are of minimal impact to the public. Sometimes the function needs to be done in the center of the night time. Sometimes areas need to be tented off to protect the public, or safeguard adjacent areas. That's all left up to the companies estimator to determine all those logistical issues.

Important thing is: If it has to be done, the right company will be able to accommodate all of these issues. Just how much area can be achieved in an average eight hour shift? Generally, about 1,000 sq. ft. with each machine and a crew of 3 people. Which includes edging, grinding with two different grits of stones, and at least two, if not three passes with diamond impregnated polishing disc's. As you can see, I still haven't answered the question about if the floor will be slick. Don't hurry me, I'm addressing it.

The quantity of polishing necessary is going to be determined by the client. Since we discussed what concrete is actually made of quite a long time back, you will understand that it is mostly clay, and sand. Ok last one! And rock. And depending what your location is at, and the age of the floor determines how much, and which type and size of rock is usually in your concrete flooring. It might be pretty regular, or it might be absolutely beautiful rock. On some jobs you are going to feel just like a jeweler polishing stones with impeccable beauty even though it may be nothing but river rock that has been buried for years. Many ordinary concrete flooring when ground and polished with good quality tools will look more like Terrazzo than concrete. Terrazzo can be a concrete mix that's poured like concrete, but includes a specific mixture of little stones or marble chips in the concrete combine which is intended to have a lot more natural beauty than concrete. But trust me, you may be surprised at what concrete can appeared as if with the proper grinding and polishing.

After the grinding and polishing is complete, you have brought out the natural beauty of the stone. It might not look like it yet, but it will, after the penetrating sealer is applied. This product is meant to penetrate the gentle "sub-strata" of your flooring. Once it really is dry to the touch, your flooring is ready for high quickness burnishing. I love Propane run burnishers which operate at 2,500 RPM. With a diamond impregnated burnishing pad the device will generate enough heat on the floor to provide out the utmost luster of the ground whether your initial concrete mix was a very sandy mix, or has a lot of excellent stones in it. One method or the additional, you will have an extremely polished floor. Your flooring will probably have the appearance of a Terrazzo or tiled ground floor with several coats of flooring finish on it.

You'll notice I don't call it wax, as many people do. That's since it isn't. Wax was not applied to floors for 25-30 years. When I initial started doing floors in the 60's, we actually used natural wax on floors. Extremely labor intensive. Next came what most people call wax. It really is a plastic item or "Thermoplastic". Which means it shines up properly when exposed to heat from a burnisher.

Note: We've the capability to wet grind and polish Terrazzo floors and apply a similar sealer eliminating the necessity to EVER strip and wax a terrazzo flooring again. This is totally revolutionary, and really should be achieved to every Terrazzo floor, in that it is much more "Green Friendly" than using caustic stripper and dumping the spent item into your sewer system several times per year. That is why these products were supposed to have been removed the market 10-15 years back.

Synthetic plastics are actually put on the very best surface of the ground. From right here on out I will refer to them in a group of "Topical Coatings". Here's whenever we get to the good part.

Topical coatings are what can in fact make the ground slick, particularly when wet. The procedure we just discussed is penetrating, not topical, which essentially makes it less slippery.

And today the cool part! Have you ever seen guys carrying big bed linens of "Plate Glass", with suction cups? Just how do they do this? I'm happy you asked. It's known as "Tension Strength". The top is so even that the cups retain connection with the glass. That's what your flooring will be like https://en.search.wordpress.com/?src=organic&q=flooring once it is properly surface, and polished.

If there is no topical product on the floor, the ground is less slippery than with color or epoxy. And when there is nothing on the top of floor it is practically scratch and chip resistant. Could it be chemical resistant? Some are much better than others, but it's only common sense that if you spill something that might damage the finish, after that clean it up as soon as possible to minimize the probability of damage.

How long does something such as this last? It depends upon the merchandise, but many manufacturers offer at least a five calendar year guarantee against any product failing. Theoretically the merchandise can last much longer with care and just a little maintenance (we.e. keeping it clean).

I don't mean to provide Epoxy a bad rap. There are various good manufacturers. They need to be mixed and used quickly by a skilled technician to avoid product failure. And, there are several that are more slide resistant than others. And that means you are going to have to trust your contractor to help you on the proper product, and look at some comparisons on the merchandise on the internet.

10 Sites To Help You Become An Expert In Who To Buy Flooring From

What is all the discuss "Polished Concrete Floors?" Polishing and grinding concrete floors has been a topic of dialogue over the past few years, and I've been asked so often what it's all about, that I decided to write this article. Hard surface floors have been around since the period of the Roman Empire. It took an enormous quantity of labor, and a lot of ingenuity to split huge stones, and hone them down to make slabs suitable for flooring in buildings. To obtain additional specific than that's mind boggling, kind of like, "How did they build the Pyramids in Egypt? " My response is, "I type of understand how they achieved it, but I'm glad I didn't want to do the work".

Fast forward just a little, and we come to newer times when people found out that you could mix Portland (a clay substance) with sand, rock and water, to make the first concrete. The mixtures have already been tweaked through the years, but the process has practically remained the same. Contractors have used different curing brokers, have implemented the usage of steel bar to ideally prevent concrete from cracking, and also have implemented different types of moisture barriers to boost on the finished item.

Building owners have wanted different types of flooring over the concrete to give a building a warmer, and cleaner feel. In industrial facilities they have used tile, rolled linoleum, floor paint, or epoxy to provide a creating a more attractive appearance, and make it easier to clean than bare concrete. That works for a while, but everyone of these products ultimately wears out and needs alternative. That brings us up for this time.

Since early in the twentieth hundred years, scientist experimented with different compositions to come up with a flooring products that would last for a long period of time. Some tile items were produced up of an asphalt bottom. Some were made stronger by adding asbestos to the blend. Do not get me wrong, it had been a good product, and after 40 years available, I've seen some asbestos tile that goes back at least 60 years, and continues to be in nice condition. The issue is that asbestos is definitely a Carcinogen, and once the tile is damaged, or disturbed, you can very easily be exposing yourself to cancer leading to agents, in the atmosphere. Guess who arrives on the noticed when something similar to that is reported? You have it! THE PEOPLE with White Hats Riding on Light Horses. Now it's time for the asbestos abatement crews. Is it possible to say, BIG BUCKS?

Abatement is a tedious, and time consuming process, but it has to be done, before you can begin the process of restoring the cement floor underneath. You cannot do it yourself! Asbestos Abatement requires a lot of time of training, certification, annual re-certification, special apparatus, and folks who are crazy plenty of to want to do it. Just kidding! Fortunately, there are individuals who enjoy that kind of work, and take pride in providing an excellent finished product.

I, much prefer coming in after the cleanup offers been completed. Concrete grinding equipment has been around the development stage for over 70 years. Changes with some companies specifically over the last 5-10 years have already been dramatic. Why? Because, the government has determined there are enough flooring out there, that are deteriorating or broken, that they have to part of with some requirements for removal, since many of these flooring are in public areas buildings. So what are my options as a services or building manager? Initial, you need to go on-collection, and look for a very reputable asbestos abatement firm, and obtain an estimate. Second, you have to find reputable Concrete Restoration firm to provide you with the options at their disposal. Next, you are likely to have to come up with a budget for the completion of the work, so that you, your plank of directors, or your school board isn't shocked by the cost of the completed task. And lastly, you will have to routine the work.

Due to the price of the abatement, and the actual fact that they will have to tent off areas as the abatement is certainly going on, you will see some dependence on some logistical planning. What you don't want to do is wait, hoping the issue will treatment itself, or go away. That's not likely to happen. It generally does not happen that often, but I have seen instances where the inspectors come in and demand that the problem is corrected before the building can be used again. That's ugly!

Do you know the definition of the term, "Problem"? It 's a predicament that you don't deal with. There are presently thousands of floors in public areas and private schools, colleges, universities, court homes, and other public buildings who've been fore warned that they need to eliminate asbestos floors.

In the last five to a decade, they have continually been given an extension, or given a "pass", because of the fact that "They don't really have money in their BUDGET". Actually, the first time I heard that was 1981, and the budget provides gotten tighter every year. This has result in the advent of gear and grinding pads for "The Do It Yourself", types. Do you know what? They don't work.

If you would like your custodian, to invest hundreds of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty year old Terrazzo, or Marble flooring, you should, GO FOR IT.

THEN WHO SHOULD I TALK TO?

You can hire a very reputable Concrete Grinding and Polishing professional, who only does floors, for much less money than you'll expect. They are able to grind, polish, seal, dye, or apply one of hundreds of products to your ground for the same or less money than re-applying tile which does not have the same resiliency, and longevity as the previous asbestos tile products.

You can install carpet which typically does not have any more than 5-7 year life expectancy. Or you can proceed with a dyed ground that will outlast most of us. Your options are endless, but you need to look for a contractor that you could trust, and execute a little homework before making your decision. Some may suggest products that you'll call floor paint or epoxy. What are the advantages or disadvantages of that kind of product? There's most likely nothing wrong with that, but you need a few facts before making your decision.

Floor paint that you'll typically buy in a home improvement or hardware shop is fairly easy to use, but generally won't hold up to much visitors, either tires or foot traffic. And in order to obtain the best results you nevertheless still need to do most of the prep that would be necessary for the other items. Epoxy is more durable once it really is cured, but could be damaged if subjected to some abuse before it is completely cured. (Two times for foot visitors) and (Up to four weeks for wheel traffic). If you cannot live with that, then you need to consider other options.

WARNING!

Epoxy is not easily repairable, and carries "NO " guarantee, if strict suggestion for it's care aren't observed. Don't expect the contractor another a week after your beautiful floor was redone to repair tire marks in your shop. It's not possible! If you prefer a floor that's less sensitive, then you should probably consider program of a penetrating dye, accompanied by sealer to give you an attractive floor surface finish which will be less susceptible to marring and scratching.

Okay, so now the questions. Are these kinds of ground finishes slippery? The easiest method to explain that's to explain the grinding and polishing procedure.

When https://www.evernote.com cement is poured you are bound to involve some inconsistencies. Why? Perhaps you have ever poured cement, or watched it getting poured? Regardless of how good you are, or how good your apparatus is, getting a large slab of concrete totally level, is next to impossible. The loads of concrete from the prepared mix company could be inconsistent in one load to the next. Most concrete is poured in the summertime when heat and wind can affect the rate of period for the concrete to dried out. Whether it's poured in the fall or winter season drying and curing agents are added to the mix which can also result in problems later on. Important thing is, the finished floor can have lots of imperfections in it that you can deal with.

The newest equipment which is normally utilized by a concrete restoration company is intended to apply more than enough pressure to the gemstone cups or "stones" under the machine that given enough time, will do an excellent job, of leveling your floor. The grinding apparatus generally weighs between 1,200 and 2,500 pounds which is a whole lot more head pressure than your swing buffer. An average grinding machine will probably have no less than twelve stone which submit a synchronized motion to pulverize the top 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Why is it softer? Because as you will recall, I talked about the curing brokers which is used at that time the concrete was poured. That product is meant to harden the top surface, and must be used off before you can really enter "Mechanically Changing" the floor. So you've got your skin off of the floor. What's next?

Next, you go to a little finer set of grinding stone to continue the grinding/leveling procedure. You go in right lines in a defined area to make sure each portion of floor is floor evenly. All flooring will demand overlapping with the device. Some will demand changing direction with the device to level the ground properly. All flooring will require edging against wall space and in doorways to grind and level the ground adequately. All this requires floor technicians with a fairly significant amount of knowledge and training to do the job the correct way.

Doesn't this create a whole lot of dust? Good issue. Yes it can, but depending on the quality of the grinding apparatus which includes some pretty high efficiency and expensive vacuums with dual "Hepa" filters, that are attached to the grinder, 90-95% of the dust is sucked directly into the vacuum to be removed. What else?

What about noise? The grinders aren't that noisy. The vacuums are, but can generally end up being operated so that they are of minimal influence to the public. Sometimes the function needs to be done in the middle of the night. Sometimes areas need to be tented off to protect the public, or protect adjacent areas. That's all left up to the companies estimator to figure out all of those logistical issues.

Bottom line is: If it needs to be done, the proper company will be able to accommodate all of these issues. Just how much area can be carried out in an average eight hour change? Generally, about 1,000 sq. ft. with each machine and a crew of 3 people. Which includes edging, grinding with two different grits of stones, and at least two, if not three passes with diamond impregnated polishing disc's. As you can see, I still haven't answered the question about whether the floor will likely be slick. Don't rush me, I'm addressing it.

The quantity of polishing necessary will likely be determined by the customer. Since we discussed what concrete is in fact made of a long time back again, you will understand that it's mostly clay, and sand. Oh yeah! And rock. And depending where you are at, and age the floor determines how much, and what type and size of rock is certainly in your concrete ground. It could be pretty ordinary, or it may be absolutely beautiful rock. On some jobs you will feel like a jeweler polishing stones with impeccable beauty even though it may be nothing but river rock that has been buried for a long time. Many ordinary concrete flooring when surface and polished with good quality apparatus will look more like Terrazzo than concrete. Terrazzo is certainly a concrete mix that is poured like concrete, but includes a specific mixture of small stones or marble chips in the concrete combine which is intended to have much more natural splendor than concrete. But trust me, you may be amazed at what concrete can appeared as if with the correct grinding and polishing.

After the grinding and polishing is complete, you have brought out the natural beauty of the stone. It might not appear to be it yet, nonetheless it will, after the penetrating sealer is applied. This product is meant to penetrate the gentle "sub-strata" of your flooring. Once it is dry to the touch, your flooring is ready for high rate burnishing. I like Propane powered burnishers which operate at 2,500 RPM. With a diamond impregnated burnishing pad the machine will create enough heat on to the floor to bring out the utmost luster of the ground whether your first concrete mix was an extremely sandy mix, or has a lot of excellent stones in it. One way or the various other, you will have an extremely polished floor. Your floor is going to have the appearance of a Terrazzo or tiled flooring floor with many coats of floor finish on it.

You'll notice I don't call it wax, as many folks do. That's since it isn't. Wax hasn't been applied to floors for 25-30 years. When I first started doing floors in the 60's, we actually used organic wax on floors. Very labor intensive. Up coming came what most people call wax. It is actually a plastic product or "Thermoplastic". That means it shines up perfectly when exposed to temperature from a burnisher.

Note: We now have the ability to wet grind and polish Terrazzo floors and apply a similar sealer eliminating the need to EVER strip and wax a terrazzo flooring again. That is totally revolutionary, and really should be achieved to every Terrazzo ground, in that it is a lot more "Green Friendly" than using caustic stripper and dumping the spent item into your sewer program several times per year. That's why these products were supposed to have been removed the market 10-15 years back.

Synthetic plastics are actually put on the top surface of the ground. From here on out I'll make reference to them in a category of "Topical Coatings". Here's whenever we get to the good part.

Topical coatings are what can actually make the ground slick, specially when wet. The procedure we just discussed is penetrating, not topical, which in essence helps it be less slippery.

And today the cool part! Have you ever seen men carrying big sheets of "Plate Cup", with suction cups? How do they do that? I'm pleased you asked. It's called "Tension Strength". The surface is so clean that the cups retain contact with the cup. That's what your flooring will probably be like once it really is properly floor, and polished.

If there is no topical product on the floor, the floor is less slippery than with paint or epoxy. And if there is nothing on the top of floor it is practically scratch and chip resistant. Is it chemical resistant? Some are better than others, but it's just common sense that if you spill something that might damage the final, after that clean it up as soon as possible to minimize the chances of damage.

How long does a product like this last? It depends on the merchandise, but many manufacturers give at least a five season warranty against any product failure. Theoretically the merchandise can last a lot longer with proper care and a little maintenance (i.e. keeping it clean).

I don't mean to provide Epoxy a bad rap. There are numerous good manufacturers. They have to be mixed and used quickly by a skilled technician to prevent product failure. And, there are some that are more slip resistant than others. Which means you will have to trust your contractor to help you on the proper product, and look at some comparisons on the products on the internet.

The Top Reasons People Succeed In The Flooring Pros Augusta Flooring Company Industry

What is all the discuss "Polished Concrete Flooring?" Polishing and grinding concrete flooring has been a topic of discussion in the last few years, and I am asked so many times what it's about, that I decided to write this article. Hard surface floors have been around because the period of the Roman Empire. It took a massive quantity of labor, and lots of ingenuity to split huge stones, and hone them down to make slabs ideal for flooring in structures. To obtain additional specific than that's mind boggling, kind of like, "How do they build the Pyramids in Egypt? " My reply is, "I type of understand how they did it, but I'm glad I didn't have to do the work".

Fast forward just a little, and we come to newer times when people discovered that you could combine Portland (a clay chemical) with sand, rock and water, to make the first concrete. The mixtures have been tweaked over the years, however the process has virtually remained the same. Contractors have used different curing brokers, have implemented the use of steel bar to ideally prevent concrete from cracking, and also have implemented various kinds of moisture barriers to boost on the finished item.

Building owners have wished various kinds of flooring over the concrete to provide a creating a warmer, and cleaner feel. In industrial facilities they have used tile, rolled linoleum, floor color, or epoxy to give a building a more attractive appearance, and make it easier to clean than bare concrete. That works for some time, but everyone of those products ultimately wears out and requires replacement. That brings us up for this time.

Since early in the twentieth hundred years, scientist attempted different compositions to create a flooring products that would last for a long period of period. Some tile items were produced up of an asphalt bottom. Some were made stronger by adding asbestos to the mix. Don't get me wrong, it was a good product, and after 40 years available, I've noticed some asbestos tile that goes back at least 60 years, and continues to be in nice condition. The problem is that asbestos is normally a Carcinogen, as soon as the tile is damaged, or disturbed, you can very easily be exposing yourself to cancer causing agents, in the air. Guess who arrives on the seen when something like that is certainly reported? You have it! THE PEOPLE with Light Hats Riding on White Horses. Now it's time for the asbestos abatement crews. Can you say, BIG BUCKS?

Abatement is a tedious, and frustrating process, but it needs to be done, before you can begin the process of restoring the cement floor underneath. You cannot do-it-yourself! Asbestos Abatement requires a lot of time of training, certification, annual re-certification, special apparatus, and people who are crazy more than enough to wish to accomplish it. Just kidding! Fortunately, there are individuals who enjoy that type of function, and take satisfaction in providing a great finished product.

I, much prefer to arrive after the cleanup has been completed. Concrete grinding apparatus has been in the development stage for over 70 years. Adjustments with some companies especially during the last 5-10 years have already been dramatic. Why? Because, the government has determined there are enough flooring out there, that are wearing out or damaged, that they have to step in with some requirements for removal, since many of these flooring are in public areas buildings. So what are my choices as a services or building manager? Initial, you need to go on-line, and find a very trustworthy asbestos abatement firm, and obtain an estimate. Second, you need to find reputable Cement Restoration firm to provide you with the options at their disposal. Next, you will have to put together a cover the completion of the task, to ensure that you, your board of directors, or your college board is not shocked by the expense of the completed task. And finally, you are going to have to routine the work.

Due to the price of the abatement, and the actual fact that they will need to tent off areas while the abatement is going on, you will have some need for some logistical planning. What you don't want to do is put it off, hoping the issue will get rid of itself, or go away. That's not going to happen. It doesn't happen that frequently, but I've seen instances where in fact the inspectors come in and demand that the issue is corrected prior to the building can be used again. That's ugly!

Which are the definition of the word, "Problem"? It 's a situation that you don't cope with. There are currently thousands of floors in public areas and private schools, schools, universities, court houses, and other public buildings who've been fore warned that they have to get rid of asbestos floors.

In the last five to ten years, they have continually been given an extension, or given a "pass", due to the fact that "They don't really have money in their BUDGET". In fact, the 1st time I heard that was 1981, and the budget offers gotten tighter every year. This has lead to the advent of apparatus and grinding pads for "The Do It Yourself", types. Guess what? They don't work.

If you would like your custodian, to spend thousands of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty year old Terrazzo, or Marble flooring, by all means, GO FOR IT.

THEN WHO SHOULD I TALK TO?

You can hire a very reputable Concrete Grinding and Polishing professional, who only does floors, for much less money than you'll expect. They are able to grind, polish, seal, dye, or apply among hundreds of products to your flooring for the same or less money than re-applying tile which does not have the same resiliency, and longevity as the prior asbestos tile products.

You can install carpet which typically has no more than 5-7 year life span. Or you can proceed with a dyed flooring that will outlast most of us. The options are endless, nevertheless, you need to look for a contractor that you could trust, and do a little homework before making your decision. Some may suggest products that you'll call floor paint or epoxy. What are advantages or disadvantages of this kind of product? There's most likely nothing wrong with that, nevertheless, you need a few facts before making your decision.

Floor paint that you would typically buy in a do-it-yourself or hardware shop is fairly easy to use, but generally will not endure to much traffic, either tires or foot traffic. And in order to get the best results you nevertheless still need to do the majority of the prep that would be necessary for the other products. Epoxy is more durable once it really is cured, but can be damaged if subjected to some misuse before it is totally cured. (Two days for foot visitors) and (Up to four weeks for wheel traffic). If you can't live with that, then you need to consider other options.

WARNING!

Epoxy is not easily repairable, and bears "NO " warranty, if strict suggestion for it's care are not observed. Don't expect the contractor to come back a week after your beautiful floor was redone to repair tire marks in your store. It's not possible! If you prefer a floor that's less sensitive, then you should probably consider application of a penetrating dye, followed by sealer to provide you with an attractive floor surface finish which will probably be less vunerable to marring and scratching.

Okay, so today the queries. Are these kinds of ground finishes slippery? The easiest method to explain that's to describe the grinding and polishing procedure.

When cement is poured you are bound to involve some inconsistencies. Why? Perhaps you have ever poured concrete, or watched it becoming poured? No matter how great you are, or how good your tools is, getting a sizable slab of concrete completely level, is next to impossible. The loads of concrete from the ready mix company can be inconsistent in one load to the next. Most concrete can be poured in the summertime when temperature and wind can affect the rate of time for the concrete to dry. Whether it's poured in the fall or winter season drying and curing brokers are added to the mix that may also result in problems later on. Bottom line is, the finished ground can have lots of imperfections in it so that you can deal with.

The latest equipment which is normally used by a concrete restoration company is intended to apply more than enough pressure to the diamond cups or "stones" beneath the machine that given enough time, will do a very good job, of leveling your floor. The grinding tools generally weighs between 1,200 and 2,500 pounds which really is a whole lot more mind pressure than your swing buffer. A typical grinding machine will have no significantly less than twelve stone which turn in a synchronized motion to pulverize the very best 1/16" to 1/8" of concrete, exposing the softer sub-strata below. Why is it softer? Because as you will recall, I talked about the curing agents which is applied at the time the concrete was poured. That product is intended to harden the very best surface, and must be taken off before you can really enter "Mechanically Changing" the floor. So you've got the skin from the floor. What's next?

Next, you go to a little finer group of grinding stone to keep the grinding/leveling procedure. You go in straight lines in a defined area to make sure each section of floor is ground evenly. All flooring will require overlapping with the machine. Some will require changing direction with the device to level the floor properly. All flooring will require edging against wall https://www.evernote.com space and in doorways to grind and level the ground adequately. All of this requires floor technicians with a pretty significant amount of experience and training to do the job the right way.

Doesn't this create a lot of dust? Good issue. Yes it can, but depending on the standard of the grinding equipment which include some pretty high efficiency and expensive vacuums with double "Hepa" filter systems, that are mounted on the grinder, 90-95% of the dust is sucked right into the vacuum to become disposed of. What else?

How about noise? The grinders are generally not that noisy. The vacuums are, but can generally end up being operated so that they are of minimal impact to the public. Sometimes the function needs to be done in the middle of the night time. Sometimes areas have to be tented off to protect the public, or shield adjacent areas. That's all left up to the companies estimator to determine all of those logistical issues.

Bottom line is: If it has to be done, the right company can accommodate all of these issues. Just how much area can be carried out in an average eight hour change? Generally, about 1,000 sq. ft. with each machine and a crew of 3 people. Which includes edging, grinding with two http://edition.cnn.com/search/?text=flooring different grits of stones, and at least two, if not really three passes with diamond impregnated polishing disc's. As you can plainly see, I still haven't answered the query about if the floor will likely be slick. Don't rush me, I'm addressing it.

The quantity of polishing necessary is going to be determined by the client. Since we discussed what concrete is actually made of quite a long time back again, you will remember that it is mostly clay, and sand. Ok last one! And rock. And depending what your location is at, and the age of the floor determines how much, and what type and size of rock is certainly in your concrete flooring. It might be pretty ordinary, or it may be absolutely beautiful rock. On some jobs you are likely to feel just like a jeweler polishing stones with impeccable beauty even though it may be nothing but river rock that is buried for a long time. Many ordinary concrete floors when ground and polished with good quality apparatus will look more like Terrazzo than concrete. Terrazzo is a concrete mix that's poured like concrete, but includes a specific mixture of small stones or marble chips in the concrete blend which is intended to have much more natural splendor than concrete. But trust me, you may be amazed at what concrete can looked like with the proper grinding and polishing.

After the grinding and polishing is complete, you have presented the natural splendor of the stone. It might not appear to be it yet, nonetheless it will, after the penetrating sealer can be applied. This product is meant to penetrate the soft "sub-strata" of your ground. Once it is dry to touch, your ground is ready for high velocity burnishing. I like Propane run burnishers which operate at 2,500 RPM. With a diamond impregnated burnishing pad the device https://www.washingtonpost.com/newssearch/?query=flooring will create enough heat on to the floor to provide out the utmost luster of the ground whether your unique concrete mix was an extremely sandy mix, or has a lot of amazing stones in it. One method or the various other, you are likely to have an extremely polished floor. Your floor is going to have the appearance of a Terrazzo or tiled floor floor with many coats of ground finish on it.

You'll notice I don't call it wax, as many people do. That's because it isn't. Wax was not applied to floors for 25-30 years. When I 1st started doing floors in the 60's, we actually used organic wax on floors. Extremely labor intensive. Next came what many people call wax. It really is a plastic item or "Thermoplastic". That means it shines up properly when exposed to warmth from a burnisher.

Note: We've the capability to wet grind and polish Terrazzo floors and apply an identical sealer eliminating the necessity to EVER strip and wax a terrazzo floor again. This is totally revolutionary, and really should be achieved to every Terrazzo ground, for the reason that it is a lot more "Green Friendly" than using caustic stripper and dumping the spent product into your sewer system several times per year. That is why these products were likely to have been taken off the market 10-15 years ago.

Synthetic plastics are actually applied to the top surface of the ground. From right here on out I will make reference to them in a group of "Topical Coatings". Here's when we get to the nice part.

Topical coatings are what can in fact make the ground slick, specially when wet. The process we just talked about is penetrating, not topical, which in essence makes it less slippery.

And today the cool part! Perhaps you have ever seen guys carrying big bed linens of "Plate Glass", with suction cups? How do they do that? I'm happy you asked. It's called "Tension Strength". The top is so simple that the cups retain connection with the cup. That's what your floor is going to be like once it is properly surface, and polished.

If there is no topical product on to the floor, the floor is less slippery than with paint or epoxy. And when there is nothing on the surface of the floor it is virtually scratch and chip resistant. Is it chemical substance resistant? Some are much better than others, but it's just common sense that if you spill a thing that might damage the final, after that clean it up as quickly as possible to minimize the probability of damage.

How long does a product such as this last? It depends on the merchandise, but many manufacturers give at least a five calendar year guarantee against any product failing. Theoretically the product can last a lot longer with care and just a little maintenance (we.e. keeping it clean).

I don't mean to give Epoxy a bad rap. There are plenty of good manufacturers. They need to be mixed and used quickly by a skilled technician to prevent product failing. And, there are several that are more slide resistant than others. Which means you are going to have to trust your contractor to advise you on the proper product, and appearance at some comparisons on the products on the internet.

Watch Out: How Flooring Show Room Is Taking Over And What To Do About It

What is all the talk about "Polished Concrete Floors?" Polishing and grinding concrete flooring has been a topic of debate over the past few years, and I am asked so often what it's all about, that I decided to write this content. Hard surface floors have been around because the period of the Roman Empire. It took an enormous quantity of labor, and a lot of ingenuity to split large stones, and hone them down to make slabs ideal for flooring in structures. To get more specific than that's mind boggling, similar to, "How did they build the Pyramids in Egypt? " My response is, "I sort of know how they achieved it, but I'm happy I didn't want to do the work".

Fast forward a little, and we come to more recent times when people found out that you could mix Portland (a clay chemical) with sand, stone and water, to make the first concrete. https://www.washingtonpost.com/newssearch/?query=flooring The mixtures have been tweaked over the years, but the process has practically remained the same. Contractors have got used different curing brokers, have implemented the use of steel bar to ideally prevent concrete from cracking, and also have implemented various kinds of moisture barriers to improve on the finished product.

Building owners have wished various kinds of flooring over the concrete to provide a building a warmer, and cleaner feel. In industrial facilities they have used tile, rolled linoleum, floor color, or epoxy to provide a creating a more appealing appearance, and make it easier to clean than bare concrete. That works for some time, but everyone of these products eventually wears out and needs substitute. That brings us up to the present time.

Since early in the twentieth century, scientist experimented with different compositions to create a flooring products that would last for an extended period of time. Some tile products were made up of an asphalt bottom. Some were made more durable by adding asbestos to the combination. Do not get me wrong, it had been an excellent product, and after 40 years in the business, I've noticed some asbestos tile that goes back at least 60 years, and is still in wonderful condition. The problem is that asbestos is a Carcinogen, as soon as the tile is broken, or disturbed, you can quickly be exposing yourself to cancer causing agents, in the atmosphere. Guess who arrives on the noticed when something similar to that is normally reported? You got it! The Guys with White colored Hats Riding on White Horses. Now you have for the asbestos abatement crews. Is it possible to say, BIG BUCKS?

Abatement is a tedious, and time consuming process, but it needs to be done, before you can begin the process of restoring the cement floor underneath. You cannot do-it-yourself! Asbestos Abatement requires a lot of time of training, certification, annual re-certification, special apparatus, and people who are crazy plenty of to wish to accomplish it. Just kidding! Luckily, there are people who enjoy that type of function, and take pride in providing an excellent finished product.

I, much prefer coming in after the cleanup provides been completed. Concrete grinding tools has been in the development stage for over 70 years. Adjustments with some companies especially over the last 5-10 years have already been dramatic. Why? Because, the federal government has determined there are enough floors out there, that are deteriorating or broken, that they need to step in with some requirements for removal, since many of these flooring are in public areas buildings. So what are my choices as a services or building manager? First, you have to go on-collection, and find a very reliable asbestos abatement firm, and get an estimate. Second, you have to find reputable Concrete Restoration firm to provide you with the options at their disposal. Next, you will definitely have to put together a budget for the completion of the task, so that you, your table of directors, or your college board is not shocked by the cost of the completed project. And lastly, you will have to routine the work.

Due to the price of the abatement, and the fact that they will have to tent off areas while the abatement is going on, you will have some dependence on some logistical planning. What you don't want to do is put it off, hoping the problem will cure itself, or disappear completely. That's not likely to happen. It doesn't happen that frequently, but I've seen instances where in fact the inspectors come in and demand that the problem is corrected prior to the building can be used again. That's ugly!

Do you know the definition of the word, "Problem"? It 's a predicament that you don't deal with. There are currently thousands of floors in public and private schools, schools, universities, court homes, and other public structures who have been fore warned that they have to eliminate asbestos floors.

Over the past five to a decade, they have continually been given an extension, or given a "pass", because of the fact that "They don't have profit their BUDGET". In fact, the very first time I noticed that was 1981, and the budget provides gotten tighter each year. This has lead to the advent of devices and grinding pads for "The Do It Yourself", types. Do you know what? They don't work.

If you want your custodian, to spend thousands of hours with a 250 RPM swing buffer, grinding grooves in your beautiful eighty 12 months old Terrazzo, or Marble floor, you should, GO FOR IT.

THEN WHO SHOULD I TALK TO?